A Professional Manufacturing Factory of Streetwear

Why Choose Lodyway

Advanced Production Facilities and Equipment

Lodyway specializes in providing high-quality custom services for well-established and market-influential brands. Our main product range includes hoodies, T-shirts, jackets, jeans, shorts, and pants.

20Years

Garment OEM Factory

10000m²

Factory Area

150000

Monthly Production

Lodyway Production Base

Showcases the full view of Lodyway’s large-scale modern factory

Sampling Room

Equipped with professional machinery and experienced sampling staff

Sample Showroom

Showcases a wide range of core products and latest design samples

Quality Inspection Department

Implements strict multi-step inspection procedures

Technical Strength

Equipped with a modern hanging production system, an independent design team, and a large-scale manufacturing base, our factory ensures high efficiency and premium quality to meet the demanding standards of brand clients.

Factory Strength

Automatic Fabric Spreading Machine

A high-efficiency automated spreading device used for accurately laying out various types of fabrics, enhancing cutting precision and overall production efficiency.

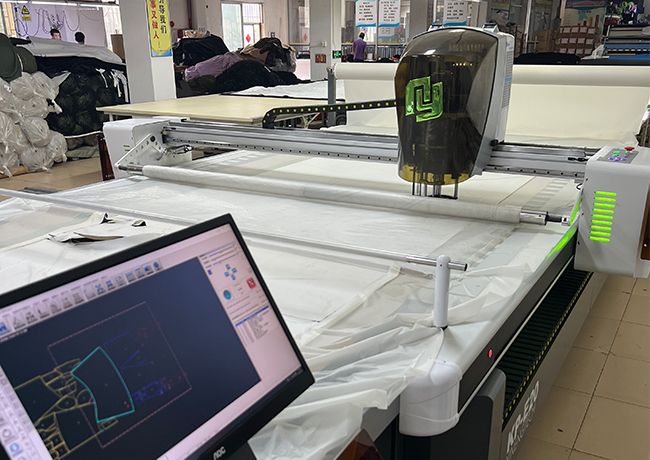

Fully Automatic Computerized Cutting Machine

Utilizes intelligent control systems and high-precision blades to efficiently and accurately cut multiple layers of fabric, ensuring production consistency and stable product quality.

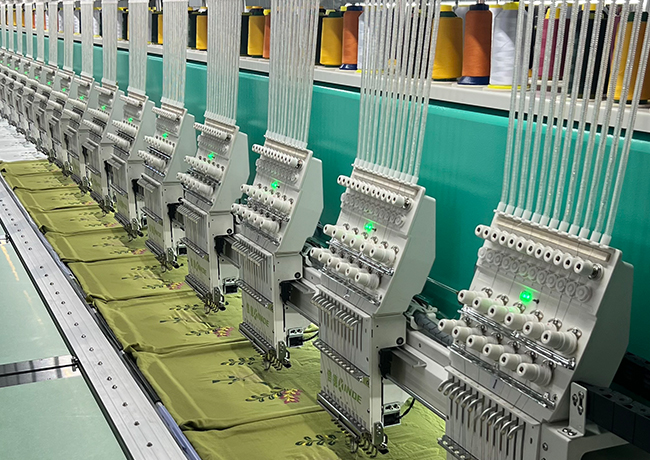

Fully Automatic Embroidery Machine

Supports various embroidery techniques such as chain stitch, flat embroidery, chenille embroidery, and sequin embroidery. Enables fast, high-quality customization of complex patterns and brand logos, meeting diverse design needs and large-scale production demands.

Manual Screen Printing Process

Supports multi-color layered printing, localized positioning, and special ink treatments, suitable for multi-style development and providing brands with diverse visual presentation solutions.

Digital Direct-to-Garment (DTG) Printing

It can accurately reproduce gradient colors, photo-quality patterns, and intricate details. Especially ideal for multi-style, high-design personalized customization. No need for printing plates, enabling fast sample production and meeting brands’ flexible manufacturing demands and the fast-paced product launches typical in e-commerce.

Cotton-Specific Digital Direct Printing

Capable of accurately rendering pattern details and color gradients, with excellent color fastness and fabric hand feel. Supports small-batch rapid production and multi-style customization, making it ideal for high-end streetwear and e-commerce brands to achieve flexible product launches and personalized design implementation.

Industrial Washing Equipment

Supports various washing techniques such as stone wash, sand wash, enzyme wash, bleaching, and snow wash. Capable of enhancing softness, creating vintage distressed effects, and strengthening textures on denim, cotton-linen, and blended fabrics, injecting unique style and premium quality into brand apparel.

Automated Hanging Assembly Line

The intelligent hanging production system is used to efficiently manage the workflow and material flow throughout the garment manufacturing process. It reduces human errors in intermediate steps, improves production pace, and ensures product consistency.

Lodyway's Supplier Network

Accessories Supplier

Sewing Thread:

We offer high-strength sewing threads in multiple colors, compatible with a wide range of fabrics and process requirements. Our threads ensure stable quality and are resistant to breakage, supporting both durability and aesthetic consistency in garment production.

Buttons:

We support customization in various materials such as resin, metal, and horn to suit different style positions. Logo printing or custom engraving is also available to highlight brand identity and uniqueness.

Zippers:

We offer customizable zippers that combine functionality with style, including high-quality options such as YKK. A variety of sizes and colors are available to meet specific design and performance needs.

Zipper Pulls:

We support customization in a variety of materials such as injection-molded plastic, metal, and webbing. Custom shapes or patterns can be developed based on your brand's specific requirements to enhance uniqueness and visual identity.

Chains:

Used for decorative accents or structural connections, these components are especially suited for streetwear and techwear designs. We offer customization in various metal materials, electroplated finishes, and thickness options to match your brand's aesthetic and functional needs.

Leather Tabs:

Ideal for jackets, denim, and other rugged menswear styles. Available in genuine or faux leather, with support for custom branding through embossing or debossing.

Logistics Suppliers

Lodyway has established long-term partnerships with 10 professional freight forwarders, supporting various logistics methods including air freight, sea freight, express delivery, and specialized small parcel routes.

Custom Hang Tag Suppliers

Care Labels:

Our care labels can display washing instructions, fiber content, and country of origin. We support multilingual printing and eco-friendly material options to meet diverse market and sustainability requirements.

Hang Tags :

We support customization of hang tags in various materials, shapes, printing methods, and punched hanging cords. Logos or collection information can also be added to enhance brand recognition and product presentation.

Fabric Suppliers

Fabrics:

Lodyway has established long-term partnerships with over 50 professional fabric suppliers, covering a wide range of fabric types including streetwear fashion, essential basics, and functional materials. We offer various options in weight, elasticity, weave, and finishing techniques to meet diverse design and performance needs.

Color Swatches:

Our swatch library includes over 300 color options, featuring solid colors, textures, gradients, and color blocking styles. We support PANTONE color matching as well as custom color development tailored to your brand’s unique palette.

Packaging Suppliers

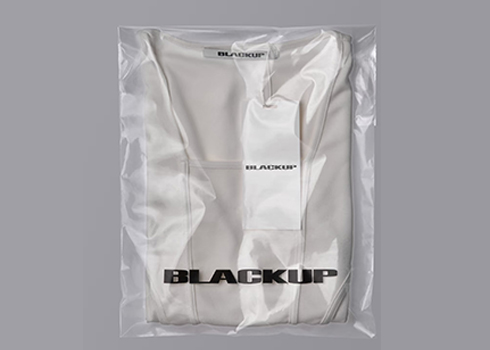

Clear Packaging Bags:

Available in various thicknesses and sealing styles, our clear packaging bags offer moisture and dust protection. They can also be customized with printed brand logos and size information to enhance both functionality and brand presentation.

Eco-Friendly Kraft Paper Bags:

Made from recyclable and biodegradable materials, these bags offer a strong visual and tactile appeal. Custom printing is available in both single-color and multi-color options to match your brand’s identity while supporting sustainability.

Woven Plastic Packaging Bags:

With strong load-bearing capacity and a durable, wear-resistant structure, these bags are ideal for secure and efficient logistics. They can be customized in various sizes and printed with brand logos to ensure safer, more organized transportation.

Industry Certification

SGS Certification

Lodyway’s factory has obtained SGS international certification, marking that we meet globally recognized standards in product quality management, production process control, and compliant operations. As a world-leading inspection, testing, and certification organization, SGS’s certification carries high credibility worldwide.

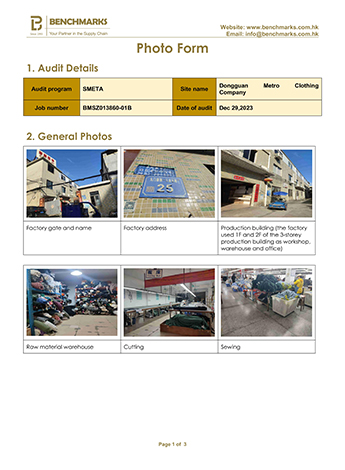

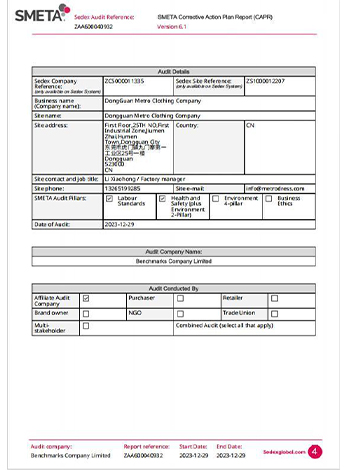

Sedex Certification

Lodyway is a registered member of Sedex and has passed the SMETA audit. This audit covers key areas such as labor standards, health and safety, environmental practices, and business ethics. It demonstrates that we meet global expectations for responsible and ethical manufacturing.

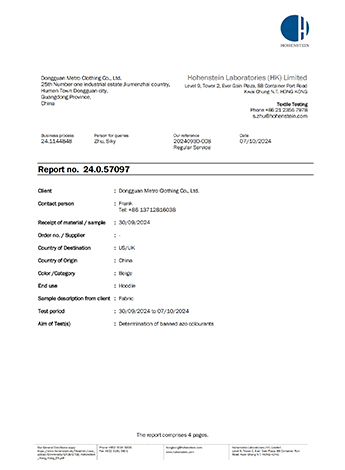

Fabric Testing Certification Report

The main fabrics used in our factory have all been certified by authoritative third-party testing organizations. The testing covers key performance and safety indicators such as colorfastness, shrinkage rate, abrasion resistance, formaldehyde content, and pH value. This ensures that the fabrics we use meet international quality and regulatory standards for comfort, environmental friendliness, and durability.

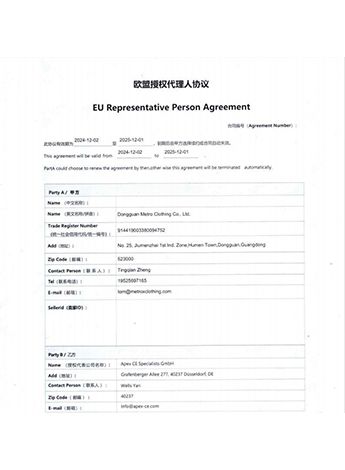

EU Authorized Representative Agreement

Lodyway has officially signed the EU Authorized Representative Agreement, ensuring that our products are compliant for sale in the European Union. This agreement covers CE certification, labeling regulations, and product safety directives, providing our brand clients with reliable support and regulatory assurance for entering the European market.

Lodyway Certificate Download

Custom Design Fashion Clothing Service Process

- Business Negotiation

Service personnel with more than five years of experience in garment industry will meet your needs. Understand your product requirements and give professional advice on your brand style

- Sample

We support the fast production of samples in ten days. We have a professional sample production department, which can perfectly produce the samples you need

- Procurement of Raw Materials

lodyway has been working with raw material suppliers for more than 20 years. These suppliers determine the stability of our mass production to ensure that every batch you receive is of the same quality

- Produce

We have professional staff with more than twenty years' experience. Five professional production lines, as well as a variety of advanced clothing production equipment, can be very good to ensure the quality of your products

- Shipping

We support all modes of transportation

- One-to-one After-sales Service

Our after-sales service is one to one, you can be completely assured of our after-sales service problems

5 STEPS OF QUALITY INSPECTIONS

RAW MATERIAL INSPECTION:

Confirm the fabric weigh, components and hand feeling whether the customer needs, and check quality of fabric whether any defects and damage pieces

CUTTING FABRIC PIECES INSPECTION:

Confirm the cutting size, shape,style are accurate by customers needs, check whether the defected pieces like: holes, tears, stains, color yarns ect.

SEWING THREADS INSPECTION:

Check the sewing stiching whether flat and smooth,whether the edges and thread ends cleaned ect.

ACCESSORIES PRODUCING INSPECTION:

Check the processing accessories whether the position are correct, whether the color and size are consistent with matching style/color.

FINISHED PRODUCT QUALITY INSPECTION:

Check whether the size and color are meets the clients requirements, whether the finished product have any uncut threads ect.